Non-Contact Clamp-On Flow Meter

Ultrasonic flow meter for the biological industry

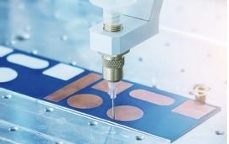

GF-KG series ultrasonic clamp-on flow sensors are compact in size, and can measure flow and output results without external circuitry. The sensors can be directly clamped on flexible plastic tubing to accurately measure the liquid flow rate and detect air bubbles. The sensors are not in direct contact with the liquid in the tubing and will not contaminate the liquid.

- High precision and high stability

- Non-invasive measurement, no direct contact with liquid, hygienic safety

- Bi-directional measurement, can calculate fluid volume and detect air bubble

- No blockage, no dead area, low fluid pressure loss

- Provide standard output methods to seamlessly integrate with customer systems

GF-KG Clamp-on Ultrasonic Flow Sensor

The GF-KS series of clamp-on ultrasonic flow sensors are compact in size and do not require an external circuit system for measurement and output. The sensor can be clamped directly to the outside of the rigid plastic pipe, the liquid flow rate in the pipe for accurate measurement, accuracy of up to ± 1.0%, and can detect air bubbles and large solid particles in the liquid impurities. The sensor does not come into direct contact with the liquid in the pipeline and does not contaminate the liquid, making it particularly suitable for applications requiring high hygienic cleanliness, such as liquid flow monitoring in biopharmaceutical processes, semiconductor equipment and medical devices.

- High accuracy and stability.

- Non-invasive measurement, no direct contact with the fluid, hygienic and safe.

- Bi-directional measurement, calculation of fluid volume, combined with bubble detection.

- No blockage, no steering, no dead space, low fluid pressure loss.

- Offers standard outputs for seamless integration with customer systems.

- Custom calibrations are available by specifying plastic hard tube material, size, temperature and fluid type.

GF-KS Clamp-on Ultrasonic Flow Sensor

Internal flow ultrasonic flow sensors are compact in size and can output results without external circuitry. These sensors can be integrated into liquid flow paths to measure very low flow rates with high accuracy. The sensors are based on the ultrasonic time-difference method technology and can be configured as flow switches or for bubble detection and liquid filling processes.

- High accuracy and stability

- Bi-directional measurement with fluid volume calculation and bubble detection function

- Circuitry is integrated within the sensor, no external circuitry is required

- Standardized output methods are available for seamless integration into customer systems.

- Fluid color or conductivity does not affect the measurement results.

GF-X5 Clamp-on Ultrasonic Flow Sensor

Coating & Filling

Since the clamp method measures on the outside of the piping, it is best suited for checking the amount of lubricant and adhesive applied, where the flow sensor cannot be installed for fear of solidification, and for checking the filling amount of food and pharmaceuticals, where contact with liquids is to be avoided.

Release Agent Spraying

Spitting & Spraying

Lubrication

When using conventional flow sensors, there is a risk of changes in production conditions due to pressure loss caused by the presence of structural components in the flow path. Therefore, it is sometimes difficult to retrofit to existing equipment. With the clamp-on type, there is no such risk and no maintenance is required.

Various measurements can be performed without contacting liquids.

No pressure loss and no change in production conditions.

Easy to install, can be quickly mounted on multiple manifolds.

It can be quickly installed on the device you wish to measure.

Clamp-on flow sensors do not require piping cuts, and no piping work is required for installation. Even complex manifolds can be easily installed with a screwdriver. The flow rate of a small amount of cooling water in the manifold and the amount of release agent applied can be visualized.

Clamp-type flow sensors can also be quickly installed when you want to manage flow rates but cannot stop production and have to postpone installation of the corresponding equipment, or when you want to install equipment for fluid liquids, such as oil, that are difficult to pipeline.

- Fluid monitoring in semiconductor processing, such as high purity water and high purity chemical reagent transfer lines.

- Medical devices such as blood dialyzers, artificial hearts, organ transplant systems, artificial heart-lung machines, blood pumps.

- Biopharmaceutical processes and equipment, such as disposable reaction vessels, fermenters, cell culture equipment, vaccine production, tangential flow filtration systems, liquid chromatographs, chromatographs.

- Food and beverage processing, filling equipment

- Spraying equipment, cooling systems, lubrication systems

- Scientific laboratory systems

Heading

Kümago Nexus GmbH

Tel : +49 211 540747 030 Fax : +49 211 540747 14 Mail : info@kuemago.com Addr : Breite Straße 22, 40213 Düsseldorf, Deutschland

@2024 Kümago All rights reserved. Terms & Conditions Privacy Policy Kümago Impressum

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.