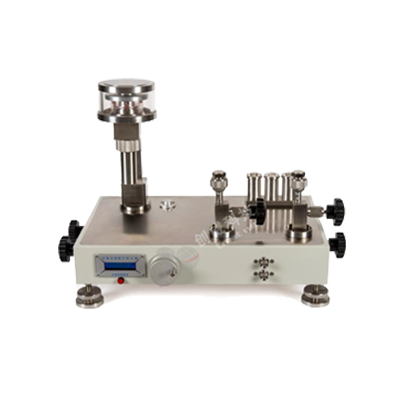

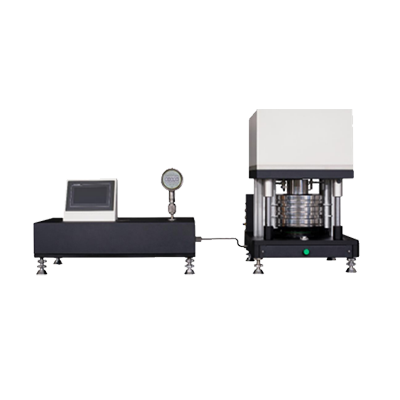

Dead Weight Tester

Dead Weight Tester for Pressure Calibration

Dead weight testers are primary pressure calibration devices that generate highly accurate pressure values by applying calibrated masses to a piston-cylinder system. They are widely used as reference standards for calibrating pressure sensors, transmitters, and gauges in industrial and laboratory environments. Their accuracy and long-term stability make them essential tools for traceable pressure calibration.

Showing all 5 resultsSorted by latest