Product categories

- Components 9

- Sensors 80

- Termperature 3

- Pressure 67

- Flow 9

- Level 0

- Force 1

- Calibration Devices 7

- Test Equipment 0

- Uncategorized 0

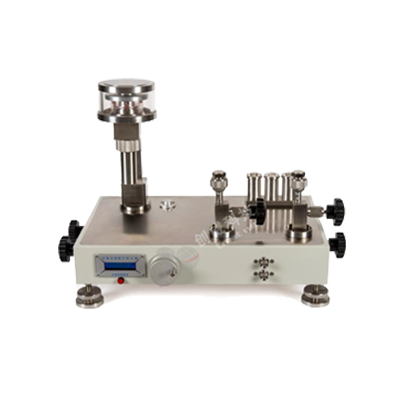

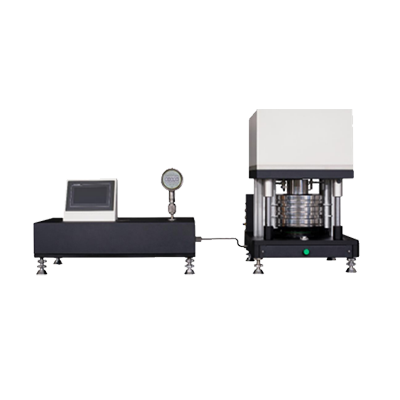

CWY Primary and Auxiliary Piston Pressure Gauge

Integrated primary and auxiliary piston system

Tungsten carbide piston and cylinder

Anti-friction, anti-jamming piston structure

Modular piston assemblies, shared base

Laser displacement monitoring, 0.01 mm resolution

Touchscreen visualization and data export

The CWY Integrated Primary and Auxiliary Piston Pressure Gauge is a high-precision standard instrument designed for pressure calibration and traceability in laboratories, metrology institutes, and demanding industrial or defense environments.

Based on the principle of hydrostatic equilibrium, the instrument realizes accurate pressure measurement through the balance between calibrated gravitational force and the effective piston area. The integrated design allows the primary piston gauge to serve as a reference for calibrating auxiliary piston gauges, while also supporting verification of digital pressure gauges, pressure sensors, transmitters, and mechanical gauges.

Both piston rods and cylinders are manufactured from high-hardness tungsten carbide, ensuring excellent wear resistance, corrosion resistance, and long-term dimensional stability. The piston system adopts a break-resistant rod design, using bearings instead of traditional limit screws to eliminate friction debris and fully prevent piston jamming. Its modular architecture allows piston assemblies to be calibrated independently, reducing maintenance effort and enabling multiple piston modules to share a single base frame.

The system incorporates a high-precision laser displacement monitoring unit based on laser triangulation technology. With a resolution of 0.01 mm, it provides real-time dual-channel monitoring of piston displacement, rotation duration, and descent velocity over a ±30 mm range. A touchscreen graphical interface displays displacement curves and operating parameters, supporting intuitive evaluation of piston performance and pressure stability. Calibration data can be exported via USB or printer, ensuring full traceability and easy system integration.