Product categories

- Components 9

- Sensors 80

- Termperature 3

- Pressure 67

- Flow 9

- Level 0

- Force 1

- Calibration Devices 7

- Test Equipment 0

- Uncategorized 0

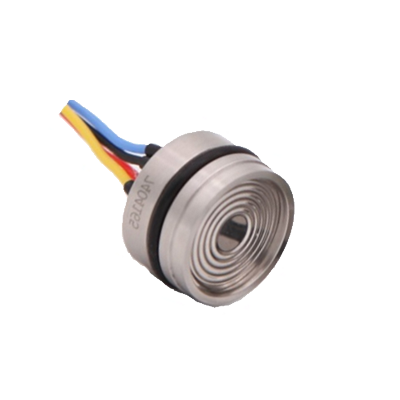

GP-2301 Hygienic Pressure Sensor

Flush diaphragm for hygienic processes

1.4435 stainless steel, polished surface

DIN 11851 hygienic process connection

AK100 safety silicone oil filling

Temperature-compensated MEMS chip

Laser-trimmed signal correction

The GP-2301 Hygienic Flush Diaphragm Pressure Sensor is specifically designed for sanitary and hygienic pressure measurement in food, beverage, pharmaceutical, and biotechnology processes.

The pressure interface and diaphragm are manufactured from 1.4435 stainless steel with a finely polished surface, minimizing dead space and preventing media residue accumulation. The flush-mounted diaphragm ensures direct pressure transmission and allows thorough cleaning, making the sensor suitable for CIP and SIP environments.

Internally, the sensor incorporates a temperature-compensated MEMS pressure chip, filled with AK100 safety-grade silicone oil to ensure stable pressure transfer and long-term reliability. Output signals are precisely adjusted using laser resistance trimming, guaranteeing consistent accuracy and repeatability over the operating temperature range.

Equipped with a DIN 11851 hygienic process connection, the GP-2301 integrates easily into standard sanitary piping systems. Its robust construction and hygienic design make it an ideal choice for applications requiring strict cleanliness, measurement stability, and compliance with hygienic process standards.