Product categories

- Components 9

- Sensors 80

- Termperature 3

- Pressure 67

- Flow 9

- Level 0

- Force 1

- Calibration Devices 7

- Test Equipment 0

- Uncategorized 0

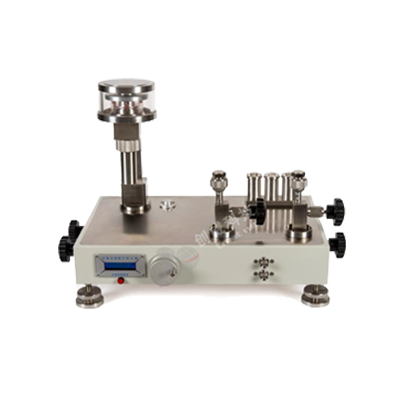

QTZ Pneumatic Dead Weight Tester

Tungsten carbide piston-cylinder

Single piston for vacuum and pressure

Modular piston, low maintenance

Non-magnetic calibrated weight set

Dual stop valves, leak protection

Fine pressure adjustment, fast stability

The QTZ pneumatic dead weight tester is designed as a primary pressure standard for high-precision pressure calibration within 10 MPa. It operates based on the fundamental pressure principle of force divided by area (F/A), where calibrated mass loads generate a precisely defined pressure at the test port.

The piston-cylinder system is manufactured entirely from tungsten carbide, providing extremely low pressure and temperature expansion coefficients. This ensures excellent linearity of the effective piston area and long-term measurement stability. The mechanical structure incorporates anti-friction and anti-break protection, enabling safe operation under both vacuum and positive pressure conditions using a single piston system.

The modular piston assembly can be removed and calibrated independently from the base unit, significantly reducing maintenance and logistics costs. The weight set is made of non-magnetic stainless steel, corrected for local gravity, and available in kg or MPa configurations to match laboratory standards.

The lightweight base, manufactured from aviation-grade aluminum alloy, integrates dual stop valves for independent vacuum and pressure control, multi-stage filtration to protect the piston system, and a fine adjustment mechanism that enables stable and precise pressure regulation without increasing installation space. The QTZ system is well suited for calibration laboratories, aerospace equipment manufacturers, and precision pressure sensor production.

Please refer other dimensions in datasheet